iSleeve Project

This project was made by Anjali Gali, Suramy Pidara and Zihao Zhu as a final project for CS 518, under the guidance of Marianne Fairbanks and Kevin Ponto.

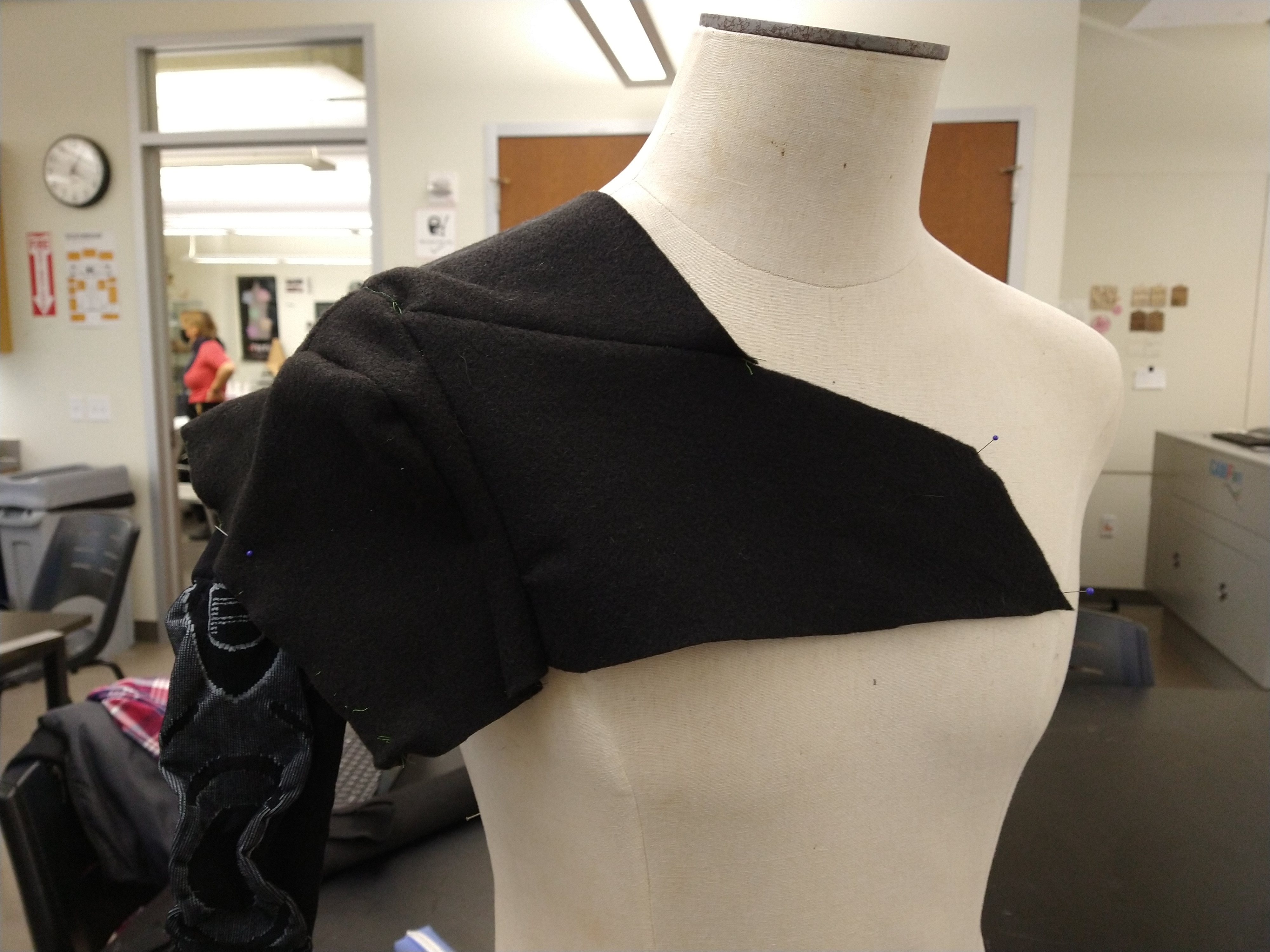

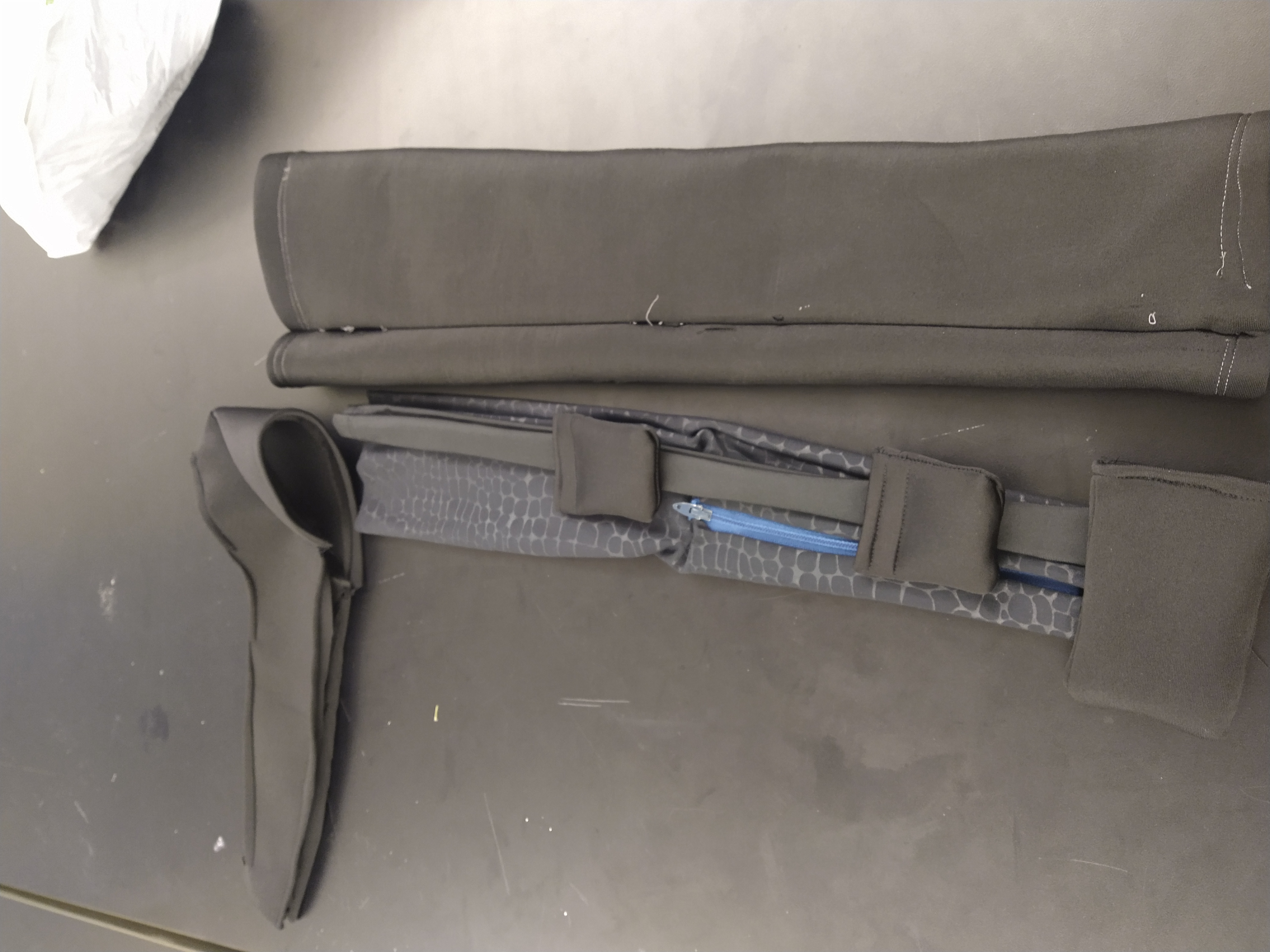

Our project uses a Compressive Sports Sleeve with a shoulder attachment as the main physical pieces of the garment. Attached to the sleeve is a Neoprene Piping that encases the circuit. We used Velcro to attach the piping to the sleeve - this way you could purchase multiple sleeves/ shoulder pieces separately and in different sizes and only one Circuit!

This would be very helpful for a team that is training one another, or family members/ friends that are spotting one another/ training together. There is a battery pack pocket that holds to the back of the shoulder using heavy duty Velcro. There is also a zip that allows a user to capture EMG Signals, to capture a users’ grip! The Garment is made using Neoprene, Micro flex Spandex, Zipper, Grommet, Parachute Buckles, and hooks to hold the pockets.

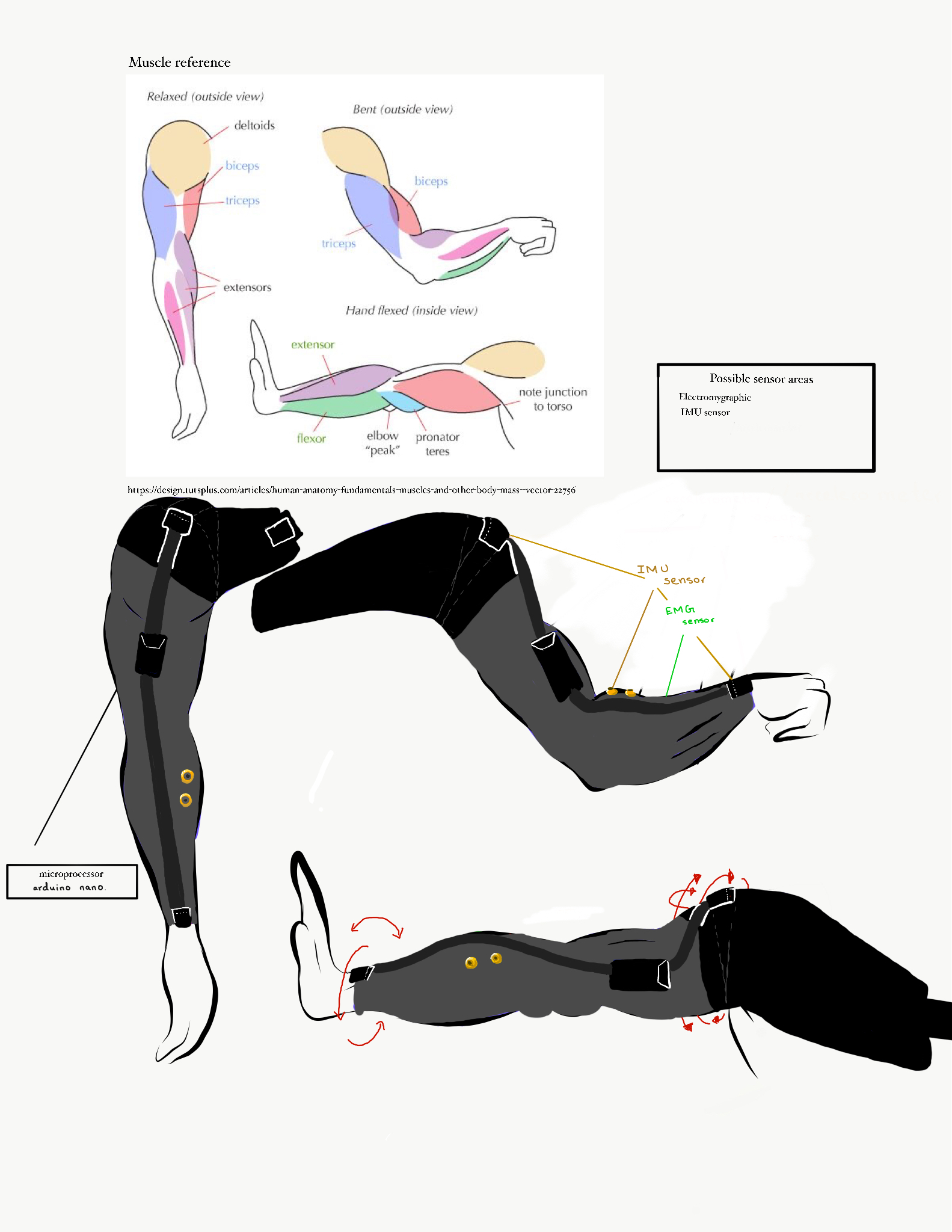

Our circuit uses an Arduino Nano RP2040 Connect as its microprocessor, a BNO055 IMU to capture movement of the forearm, the LSMD6SOX IMU (onboard the Arduino Nano RP2040 Connect) to capture movement of the upper arm, and the MyoWare EMG Sensor to capture grip information. The IMUs and EMG Sensor use I2C Communication to send signals to the microprocessor. The microprocessor is powered by the battery pack on the shoulder.To process the data we used the Arduino Genuino IDE and Blender Python.

Arduino Genuino IDE collects the preprocessed Accelerometer, Gyroscope and Magnetometer/ Temperature data and runs it through the Madgwick Algorithm to collect roll, pitch, and yaw. Arduino then sends this data via Wi-Fi to Blender, which collects each coordinate, and uses it to change the position of the bone attached to the mesh. Over time and collection of data, the arm movements reflect the live motion of the arm of the use

I was responsible for the fabric selection and 3D Modeling. A fun fact is that for this project I had to learn sewing and garment design skills! Although we started by making a prototype with Neoprene, we realized Neoprene did not have the stretch we looking for with our compressive sleeve. We experimented with a couple of sleeves from Dicks Sporting Goods but realized we couldn’t cut through them because it would ruin the knit fabric. So we purchased Micro flex Spandex from Joanne’s Fabrics and made our final glove using that, which further allowed us to cut without fraying the fabric and cooled the skin.